Digital Twin based Simulation & Optimization.

Unlock the power of real-time planning throughout your entire supply chain - from production scheduling to S&OP - optimized and able to adapt to dynamic conditions.

We turn challenges into opportunities.

Experience the power of our cutting-edge software, harnessing state-of-the-art algorithms and AI technology.

- Real-Time Scheduling

- Seamlessly create and optimize your production & logistic plans, ensuring efficient resource allocation and maximizing productivity.Learn more

- AI-based S&OP

- Streamline and enhance your strategic decision-making processes by leveraging AI to align sales and operations, driving profitability and customer satisfaction.Learn more

- Portfolio Optimization

- Optimize your product portfolio mix, pricing strategies, and market positioning to maximize profitability, meet customer demands, and drive sustainable growth in a competitive market.Under development...

- Network Optimization

- Unlock the potential of your supply chain by optimizing the network design to minimize costs, enhance efficiency, and improve overall performance.Under development...

Leverage supply chain dynamics to drive success.

Or what makes us special.

Probabilistic Digital Twin Model

Gain a competitive edge with our Probabilistic Digital Twin Model, leveraging a digital replica that mirrors your systems and supply chain behavior.

Adaptive Optimization

Use our AI Optimization to conquer the ever-changing dynamics of real-world supply chains and thrive amidst uncertainty. Unleash the full potential of your business.

Thrive amid disruption.Reinvent your supply chain with AI.

Recurring disruptions reinforce the need for a fundamental reinvention to achieve critical levels of agility and resilience according to Gartner annual survey of 1,000 supply chain leaders.

Industries we work with.

Stay one step ahead of changing operational conditions with our dynamic and intelligent approach.

Process Industry

Optimize your production processes and achieve seamless coordination from raw materials to final products.

Logistics

Streamline your logistics operations and enhance efficiency at every step.

Manufacturing

Revolutionize your manufacturing processes and achieve optimal resource allocation and scheduling.

Let's work together

Discover how our software can revolutionize your business today!

Frequently asked questions

If you can’t find what you’re looking for, please quickly reach out to us and a member of our team will discuss your matter with you shortly.

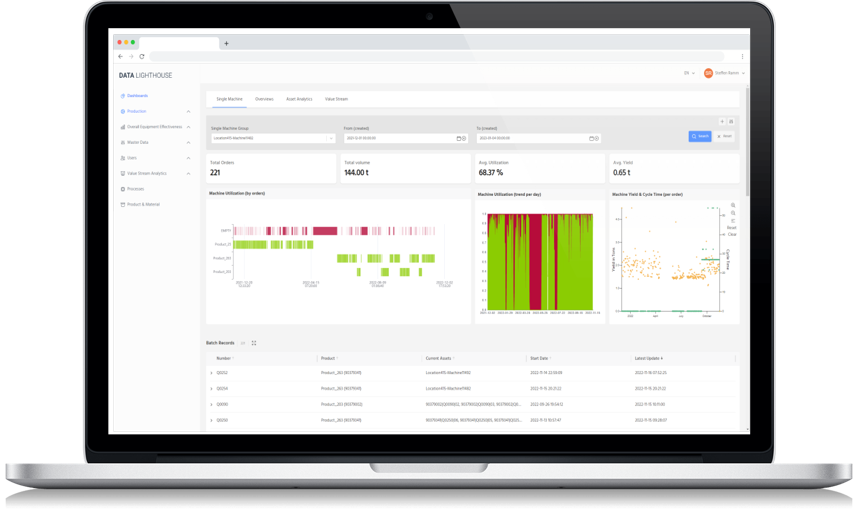

Which data do you need?

This may vary by the use case. General speaking we use historical data of the produced orders including exact utilizations as well as material inputs and outputs. This can be extracted from different sources, e. g. historians, MES or batch servers.

Does our data leave our systems?

We are providing a single tenant application environment per customer, which can be deployed on-premises or in any preferred cloud environment such as Azure or GCP. In short: No, you have full control over your data.

Do you use our data for anything else?

No. Our agreement prohibits us to use your data for anything else than providing our services and applications to you.

What can I do if my data is very corrupt and even missing data?

Even partially broken datasets can be used to generate valuable models to help in optimizing your supply chain. Nevertheless, we also do have solutions to support you to collect better data.

To which systems do you need access?

Depending on the use case we need to receive data from all factory machines, warehouses and planning systems. This usually includes historians, MES and WMS within plants/ warehouses and ERP systems for general administration.

How can I be sure, that your solutions will work?

We are happy to conduct a short pre-study with you to clarify exactly what you can expect from our solution given your expectations and existing data/ systems.

How can we calculate an ROI on the project?

We can provide you with estimated inventory/ lead-time reductions for different implementation maturities. Based on reduced capital cost, additional free cashflow, reduced cash-to-cash cycle time and reduced material holding cost, we can usually provide a clear ROI.